Beverages require reliable beverage packaging machines that can properly fill and seal various types of products. You’ll find one of the best selections of used beverage packaging equipment here at High Performance Packaging. We have plenty of high-quality packaging machines that can give your facilities what they need to give you the best results.

Get Dependable Used Beverage Packaging Machines

We carry one of the most expansive selections of used beverage packaging equipment for installation in many different types of production lines and facilities. We have plenty of equipment that can meet the needs of any application, customizable for various packaging specifications.

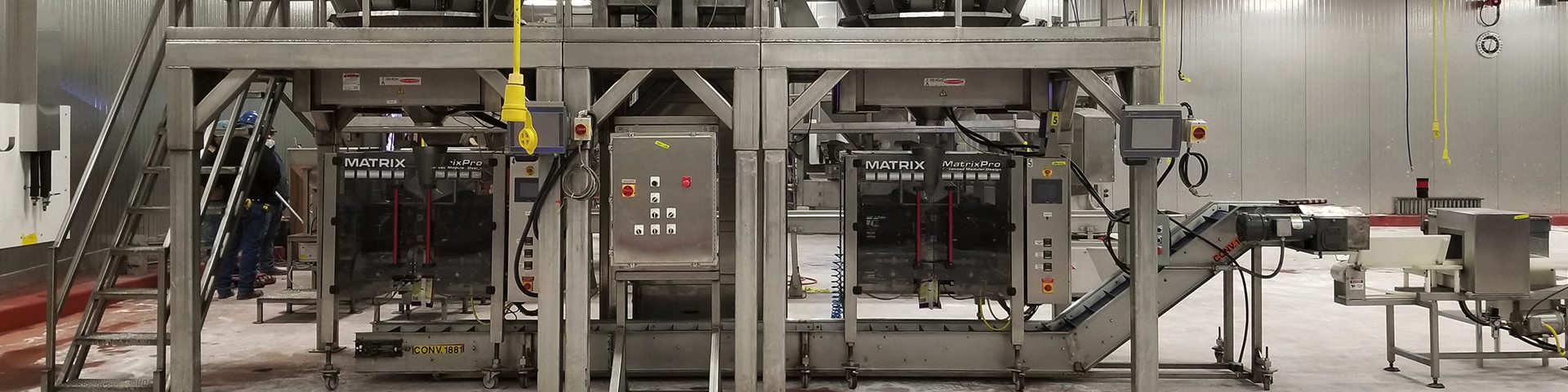

Our inventory includes a collection of reliable HFFS and VFFS machines, conveyors, bucket elevators, combination weigher scales, labelers, and much more. We also help ensure consistent quality by only carrying equipment from the top brands in the industry, including Bartelt, Yamato, Ishida, Kliklok, Matrix, Hayssen, and many others. You’ll never need to be concerned about frequent breakdowns and downtime with high-quality used equipment that can still function for many years.

Why Turn to High Performance Packaging?

What sets High Performance Packaging apart from other companies is our devotion to quality and customer service, only offering the most reliable used beverage packaging machines available. We want to make sure all of our customers are continually happy with the equipment they purchase, with machinery that’s in working condition. We test each piece of equipment to ensure functionality before selling, and we also carry replacement parts such as forming tubes and sealing bars to further make sure your machines work the way they should.

Get Services to Make the Most of Your Used Beverage Packaging Machinery

To leave you even more satisfied with your purchase, we offer several services in addition to top-quality packaging equipment. Our list of services includes operator training, equipment troubleshooting, preventative maintenance, line startups, performance improvement, and an OEE program. Each of these services can help contribute to a fully operational packaging line that maximizes efficiency, effectiveness, and profitability, with minimal risk of breakdowns and costly downtime.

To get started on finding the perfect packaging equipment for your beverage packaging systems today, contact High Performance Packaging and we’ll connect you with one of our industry experts. You can also browse our entire inventory online and request a quote for any of our available products. We’ll help you find exactly what your facility needs to maximize productivity and efficiency with our unrivaled products and services.

Different types of dairy products require different systems of reliable packaging machinery. To reduce costs and build a long-lasting system that works for your specific application, consider purchasing used dairy product packaging machinery instead of new models. Trusted companies like High Performance Packaging offer used fillers and other types of packaging equipment without any decrease in quality.

Different types of dairy products require different systems of reliable packaging machinery. To reduce costs and build a long-lasting system that works for your specific application, consider purchasing used dairy product packaging machinery instead of new models. Trusted companies like High Performance Packaging offer used fillers and other types of packaging equipment without any decrease in quality.