There are many uses for Multivac packaging machinery. Their thermoforming and vacuum packaging machines help keep food items fresh, and their heavy-duty construction makes them ready for many years of use. Multivac equipment is some of the most reliable in food processing and packaging, which is why High Performance Packaging recirculates models from this manufacturer along with other types of used packaging machines. Their high-quality construction makes them ideal for reselling and repurposing, as many companies rely on them in their production lines.

Top-Quality Thermoforming and Vacuum Packaging Machines

Multivac manufactures thermoforming machines and vacuum packagers that produce packages that effectively contain the fresh food products. Meat, fruits, vegetables and other perishables benefit from airtight packages that are ready for shipping to grocery stores and other locations. Multivac builds its equipment to be as fast and efficient as it should be in food processing facilities, using some of the toughest materials.

Thermoforming machines from Multivac can produce packages that maintain freshness of contained products while allowing customers easy access to the product. For instance, some thermoformed packages can include a corner tab that customers can pull to conveniently open the container. Vacuum packaging machines effectively remove all air from packages containing various types of spoilable foods, maximizing their shelf life. They are capable of packaging products at high rates as well. Many types of companies depend on Multivac packaging machinery for its combination of quality and efficiency.

Buying Used Multivac Packaging Machinery

New Multivac packaging equipment may tempt a lot of companies, but there are additional benefits to purchasing used thermoforming and vacuum packaging machines from used packaging machine companies. The most obvious benefit may be the lowered cost of buying used machines, but there is no sacrifice in quality when getting it from the right company. A reliable packaging company will inspect used equipment before reselling it, ensuring that any future customer receives machinery that’s in working condition and ready to ship.

Another benefit is the fact that good packaging companies will offer other services in addition to the used Multivac packaging machinery. Operator training is a service that certain companies provide, helping to make sure that your employees understand how the equipment works as well as what to look for in the event of a malfunction. Preventative maintenance services are also important to maximize the longevity of the packaging equipment, and replacement parts are also often required if a component experiences wear or damage. Identifying a single faulty part and replacing it can save you the costs and frustration of buying an entire replacement packaging machine when you don’t need it.

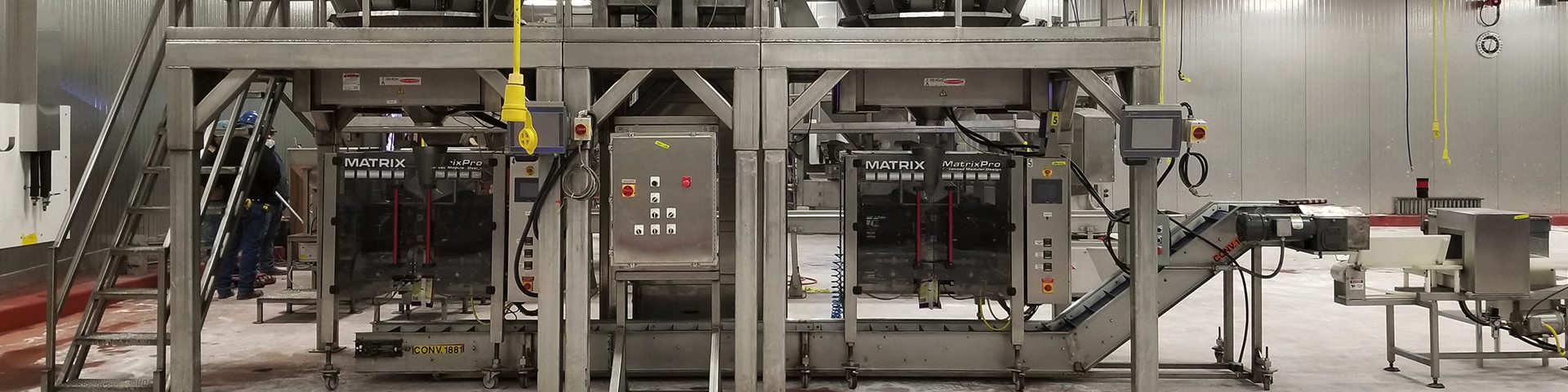

High Performance Packaging carries used models of Multivac packaging equipment along with many other top brands in the packaging industry. We have supplies that cover a wide range of industries, for both food and nonfood products. Our full inventory includes a selection of VFFS machines, case sealers, label printers, applicators, and many others.