In your line of work, time equals money. The more product you can package in a certain time frame, the better. Increasing your line speeds, for that reason alone, is a great thing. But how do you do it? There are a few different ways, and once you know these helpful tips, you’ll be surprised you didn’t look into it earlier.

First Things First: Training

The first thing you can do to increase your line speeds is to ensure that all of your employees are adequately trained on the machinery you’re using. If they have any hesitancy when it comes to doing their work, this can snowball and waste a lot of time over the course of a day, a week, or a month. Another thing to consider is to train employees on more than just the machine they primarily use—that way, if someone is out sick, another employee can easily take their place, resulting in no downtime.

Identify Slow Spots – Monitor the Line

Next, you’ll want to monitor your line closely to identify any slow spots. This can be done either manually or with cameras to reveal places where the line slows down. This could be a scale that isn’t accurate enough to move packages along quickly, a capping machine that has trouble fitting the caps to the container, or any number of other sections that don’t work as efficiently as they could. Once you identify the problem areas, you’ll know what you need to do next.

Automate Time-Costing Sections

Once you’ve located problem areas, you’ll be able to make decisions regarding what to do to remedy the issue. For instance, if it’s an issue of a part being worn down, you can replace the part. If the entire machine is working improperly, you can talk to a technician about repairs or replacement, if that’s necessary. If you’re noticing a bigger problem—for instance, your team has to manually add caps to containers instead of letting a machine do it, you can decide to automate that part of the line.

Boost Employee Morale

Finally, another step you can take to help speed up the work process in your plant is to boost employee morale. This is a bit more involved, but happy employees who feel like their job is important and necessary will feel more inclined to do their work better and more quickly. Look into ways to improve your staff’s attitude and morale, and you might be pleasantly surprised at how much productivity can increase.

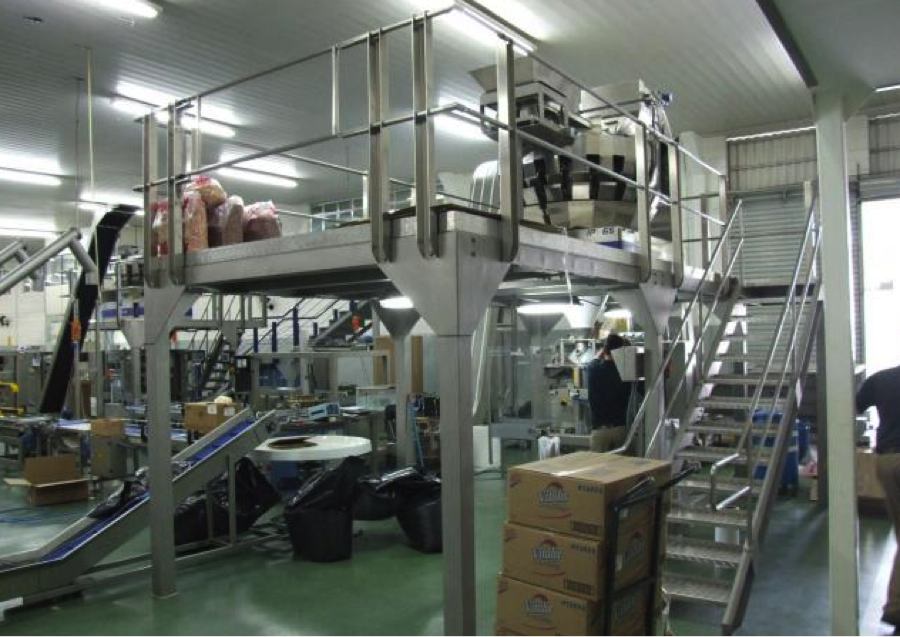

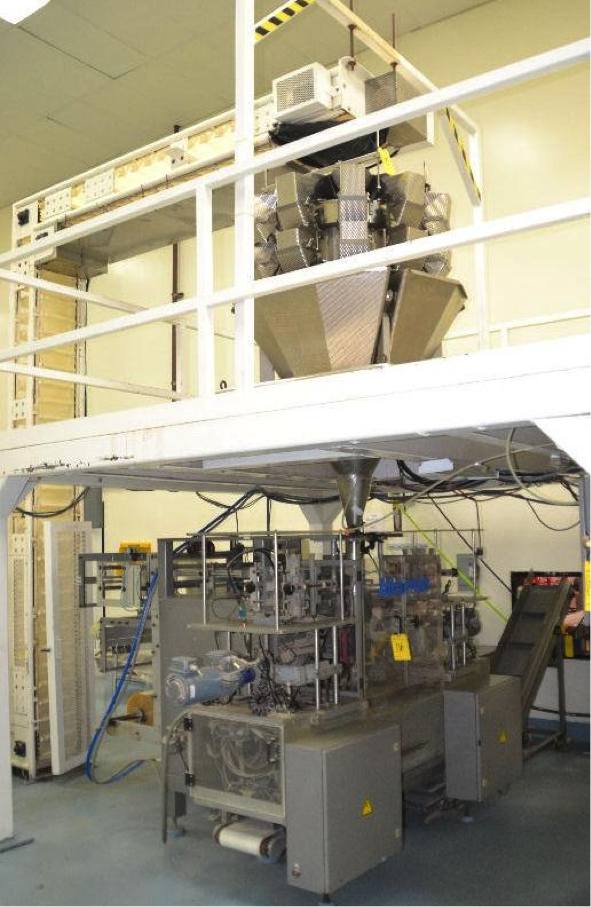

One of the main industries that use packaging machinery is the food industry. Without machines, the packaging process would not only be inconsistent, but it would be much slower. With machines, companies are able to package consistent weights of their product, which is not only good for aesthetic reasons, but it also ensures no money is lost either from overfilling the product or underfilling—which may result in unhappy customers. Aside from weighing, used packaging machines can be used to seal products like frozen pizza, individual condiment packets, and much more.

One of the main industries that use packaging machinery is the food industry. Without machines, the packaging process would not only be inconsistent, but it would be much slower. With machines, companies are able to package consistent weights of their product, which is not only good for aesthetic reasons, but it also ensures no money is lost either from overfilling the product or underfilling—which may result in unhappy customers. Aside from weighing, used packaging machines can be used to seal products like frozen pizza, individual condiment packets, and much more.