If you’re in the market for new or refurbished packaging machinery, it’s likely you’ve been doing a lot of research regarding some of the best brands out there. No matter what specific machine you’re looking to purchase, it can’t hurt to learn a bit about a few of the most widely known manufacturers—and perhaps find out why they are so well known.

Hayssen

Hayssen Sandiacre is a manufacturer of a few different types of packaging machines, including VFFS baggers, HFFS flow wrappers, packaging feed systems, and more. They have been producing high quality packaging machinery for over 100 years, and are committed to creating flexible packaging solutions for a number of industries. They manufacture complete packaging lines for a number of products, such as dried pastas, snack foods, pet food, powders, non-food packaging, and much more. With the range of different products they offer, depending on your industry, you will likely be able to find what you need for your packaging line.

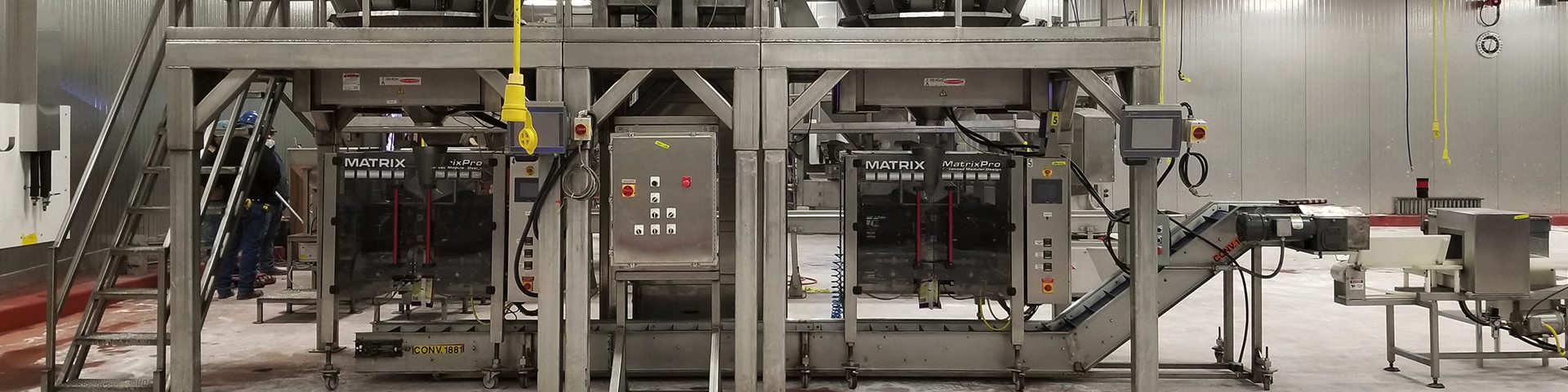

Matrix

Matrix was founded in 1988 and has since been delivering well-engineered and competitively priced packaging machines and systems to industries that need it. They are currently an industry-leading manufacturer of vertical form fill seal (VFFS) machinery. Their machines are designed to optimize performance and expedite the shipping process. At High Performance Packaging, we are proud to offer our clients the option to purchase refurbished Matrix machinery for their businesses.

Combi

For over 30 years, Combi has manufactured food-safe machinery for packaging lines. They create weighers that are more ideal for the food industry than conventional scales, as their products are designed in such a way that they are more easily cleaned and are less susceptible to water damage during the cleaning process. For businesses looking to streamline their packaging lines, Combi scales are a great choice—and when you purchase from High Performance Packaging, you can get a great price on a refurbished, top-of-the-line machine.

If you’re in the market for packaging machines, consider purchasing your equipment used or refurbished. While you may think that is a risky thing to do or that you’ll end up with a machine that is less reliable than a new machine, that’s simply not the case. Refurbished packaging machinery such as used vertical form fill and seal machines or used combination scales are just as reliable as new machines, but you’ll spend much less on them. Besides saving money, however, what are some of the other benefits of choosing to purchase used machinery for your packaging line?

If you’re in the market for packaging machines, consider purchasing your equipment used or refurbished. While you may think that is a risky thing to do or that you’ll end up with a machine that is less reliable than a new machine, that’s simply not the case. Refurbished packaging machinery such as used vertical form fill and seal machines or used combination scales are just as reliable as new machines, but you’ll spend much less on them. Besides saving money, however, what are some of the other benefits of choosing to purchase used machinery for your packaging line?