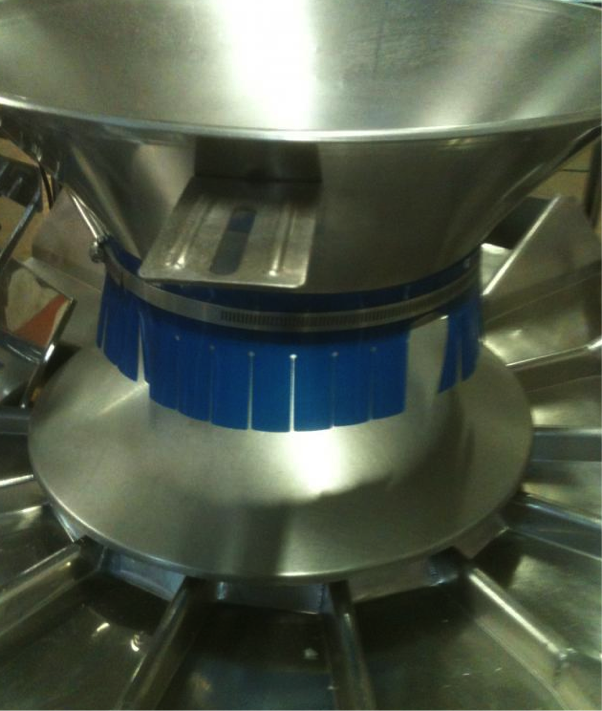

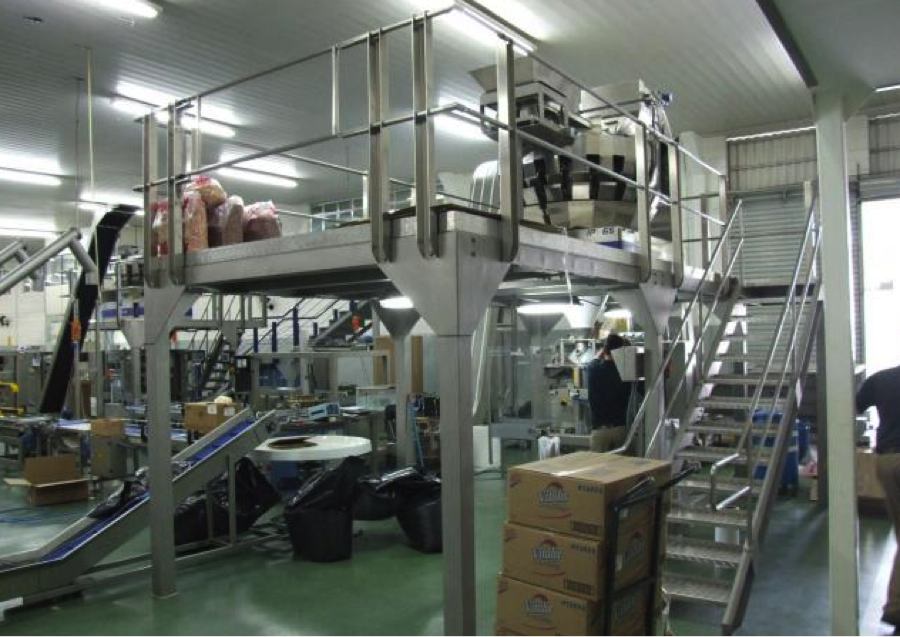

Combination scales are an essential machine for many companies’ packaging lines. These scales are able to weigh out different components of product and package them into the same container or bag. Combination weighers facilitate the process of packaging a combined assortment of goods into the same package, so it’s important to use one that does so efficiently. In the packaging machinery industry, there are a number of companies that manufacture these machines. Learn more about some of the leading manufacturers before you make your decision on which to buy.

Bilwinco

Bilwinco offers a range of scales that cover portion sizes from 10 grams up to 500 kilograms, for a total output of up to 300 kilograms per minute. Ideal for dry foods, these weighers are known for being some of the best in the business. Bilwinco has been a market leader in weighing and packaging industries since 1955 and is headquartered in Denmark. The company also develops and builds custom-made solutions for its clients.

Combi

Combi is another company known for its high-quality scales and weighers. They are behind the PrimoCombi, the first open frame combination scale with an electronic control panel that can be conveniently placed anywhere. Typically, other brands’ scales have the scale located at the base of the scale, which can make cleaning the machinery more difficult. Combi was founded in 1991 and has since delivered packaging systems to more than 30 countries. It has facilities in Las Vegas, Montreal, Toronto and Miami.

Ishida

With a network extending to 70 countries, Ishida is a leading manufacturer of weighing and packaging machinery. The company is currently celebrating its 120th anniversary, so they’re a company you can rely on to be here when you need them. In addition to manufacturing high-quality combination scales and multihead weighers, they also make conveyors, snack food bag makers, automatic wrappers, platform scales, and a number of other machines.

Multipond

At Multipond, the focus is on producing some of the best known multihead weighers out there. Serving both food and non-food companies, these machines are designed to deliver individual computer combination weigher abilities that companies can trust for accuracy. Multipond has been in business since 1987, and is positioned as one of the market leading innovators in the industry.

Parsons Eagle

With more than 90 years of experience, Parsons Eagle serves specific markets including pet food, pet treats, fresh fruit, cereals, confections and more. Parsons Eagle Packaging Systems is a division of Campbell Wrapper Corporation of De Pere, WI, and is also a leading supplier of horizontal flow wrapping and form/fill/seal packaging solutions. They offer dependable, high performance packaging equipment for a variety of industries.

Yamato

Another leader in this business is Yamato. With roots dating back to 1922, this company is here to stay. Yamato offers an array of different packaging machines, and their combination scales and weighers are available in more than 100 different models with varying features. The company is headquartered in Mequon, Wisconsin, and the line of products address virtually any packaging needs.

Want to learn more about any of these brands? Contact High Performance Packaging today!