When you’re trying to save money in your budget, it can be hard to find places you can cut costs, especially if you need to purchase new machinery for your packaging line. Thankfully, though, buying used machinery can save your company thousands of dollars, and not just at the time of purchase. There are a few different ways that purchasing used equipment can save your company money over the long term.

Initial Purchase Price

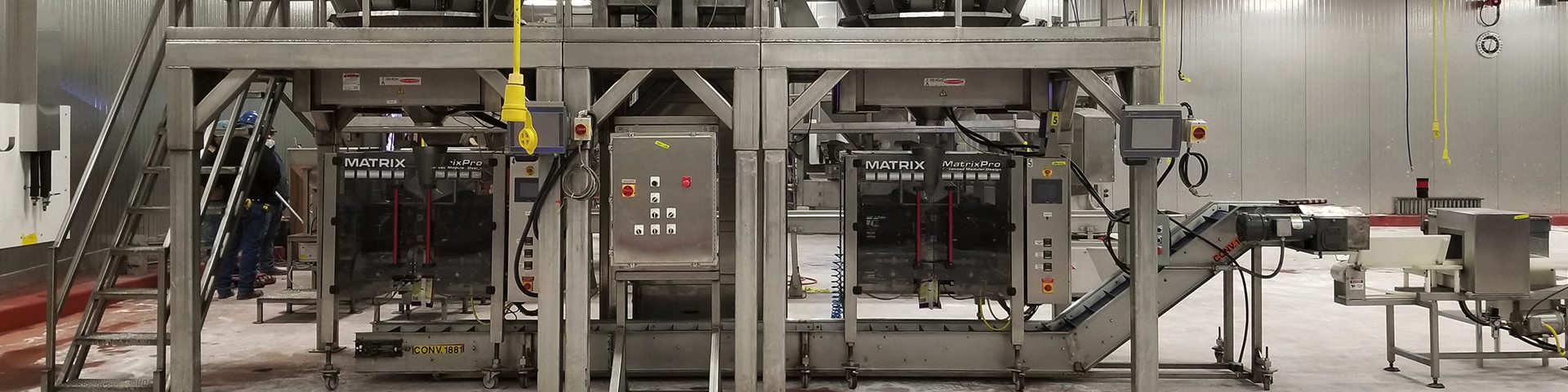

Of course, the most obvious way that purchasing used equipment can save you money is at the outset—spending less money to outfit your production line is a straightforward method of cutting costs when you need new machines. Used machinery will still provide your business with years of reliable service, but at a fraction of the cost that purchasing all new machines would. Furthermore, since you save by buying used, you may be able to purchase more than one machine, which, while it may not reduce your costs, can increase your output.

Refurbished May Work Better

When you’re working with a budget, you may not be able to afford the newest model of a certain machine. If you choose a refurbished or used model, however, you may be able to get a newer model, which, theoretically, will work more efficiently than older models that are brand new. When you work with more efficient machines, you’ll save the company money since the refurbished packaging machines will likely be better at doing their jobs than older models. That means fewer mechanical failures, less downtime, and less time spent fixing problems and troubleshooting. This not only saves you money with the purchase of the product itself, but with time wasted spent trying to fix issues you are having with a particular machine .

As the years go on, you’ll find that used machinery will work just as well as new machinery—refurbished means that the machines have been fully inspected to ensure their efficiency and durability.

You know that packing machinery is an integral part of the way your company makes money, so why not use the most efficient method of doing so? Choose used and refurbished models and save money while you make money.